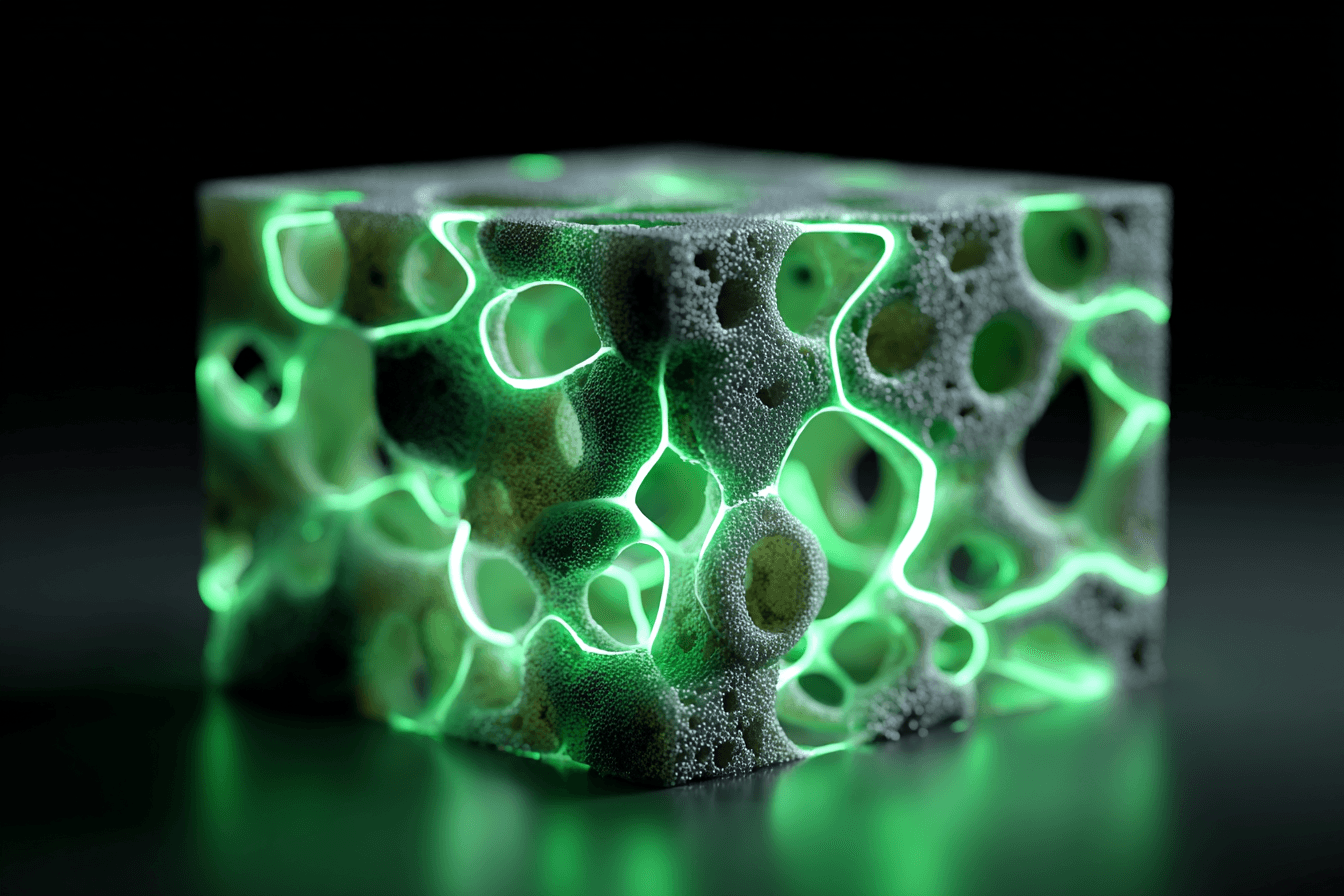

INTERFACE & PRIMER COATINGS

Coatings on active materials, current collectors, and other interfaces to improve mechanical properties, adhesion, cycling stability, and energy density with ultra-thin, conductive, and chemically stable eGraphene layers.

Especially, next-gen high-energy or dry-processed batteries are facing challenges at their interfaces. Where electrodes, current collectors, and electrolytes meet, poor adhesion, unstable contacts due to swelling or plating of active materials, and side reactions can lead to loss of conductivity, active material, and voids, as well as dendrite growth. These interfacial instabilities degrade performance, safety, and lifetime — long before the active materials reach their theoretical limits.

Active Material Coating

On both cathode and anode materials, eGraphene forms stable, uniform, conductive coatings that stabilize particle contact and improve electronic pathways.

Current Collector Coating

Applied as an ultra-thin primer, eGraphene enhances adhesion, conductivity, and corrosion resistance between metal foils and electrode layers.

Li-Metal Interface Coating

Between the current collector and Li-metal anodes, eGraphene forms a conductive, chemically stable interlayer that ensures uniform lithium plating and prevents void or dendrite formation.

10 years

R&D

10+

global patents

€ 2,6 m

total funding

50 t/a

dispersion capacity

100+

customization options

INTRODUCING

eGRAPHENE

eGraphene is a few-layer, electrochemically exfoliated, and functionalized graphene made by a patented water-based process. Ready-to-use formulations provide a unique combination of chemical stability, electrical conductivity, and mechanical adhesion at the interface — achieved at very low loadings.

Want to know more about eGraphene?

Ultra thin, ultra low loading

Superior conductivity

1000

Cycles with less than 20% capacity degradation measured in a Lithium-Metal battery

10%

More energy density measured for Lithium-Metal battery

High chemical stability

Strong mechanical adhesion

CONTACT

Better products start with better materials: We have 8+ years of experience applying eGraphenes to various applications and are ready to support you. Reach out to our experts.

Supported by:

FAQ

If anything in our FAQ isn't answered, don't hesitate to contact us.

BATTERY

USE CASES

By being 52x more conductive than carbon black and 30x cheaper than SWCNT, eGraphene is a next-gen carbon material that boosts conductivity as a conductive additive, stabilizes interfaces, and improves separator performance.

Electrode Conductive Additives

A novel conductive additive to complement or replace Carbon Black & CNTs for cathodes and anodes.

Interface & Primer Coatings

Coatings on active materials, current collectors, and other interfaces to improve cycling stability and energy density.

Separator & Membrane Coatings

Enhance or replace PFAS-based separators and membranes in redox-flow systems and fuel cells.

CAREER

We’re scientists, engineers, and builders — working to unlock the era of 2D materials. Backed by strong funding and partners, Sixonia is scaling fast — and always open to exceptional people.