CONDUCTIVE ADDITIVE

Upgrade your electrodes with eGraphene — 52× more conductive than carbon black and up to 30× cheaper than SWCNTs, for high-performance cathodes and anodes.

Today’s conductive additives force a trade-off: Carbon black is easy to use but has low conductivity, limiting electrode performance and energy density. SWCNTs enable high-performance cells but come with a high cost per kWh and complex processing. Cell manufacturers need a conductive additive that delivers high conductivity without cost or processing penalties — scalable, stable, and easy to integrate.

NMC & LFP Cathodes

High-performance cathodes need conductive networks that outperform carbon black in conductivity while avoiding the high material cost and processing complexity of SWCNTs.

Si, LTO & SiOx Anodes

Advanced anodes require high-conductivity networks — with the added need for pathways that stay intact during volume changes and SEI growth to ensure long-term cycling stability.

INTRODUCING

eGRAPHENE

eGraphene is a few-layer, electrochemically exfoliated and functionalized graphene made through a patented water-based process and supplied as ready-to-use formulations. They establish a highly efficient conductive network in cathodes and anodes alike, delivering performance and cost benefits without the trade-offs of carbon black or CNTs — a true next-generation conductive additive.

10 years

R&D

10+

global patents

€ 2,6 m

total funding

50 t/a

dispersion capacity

100+

customization options

Navigate quickly to your section of interest.

1

CATHODE

PERFORMANCE

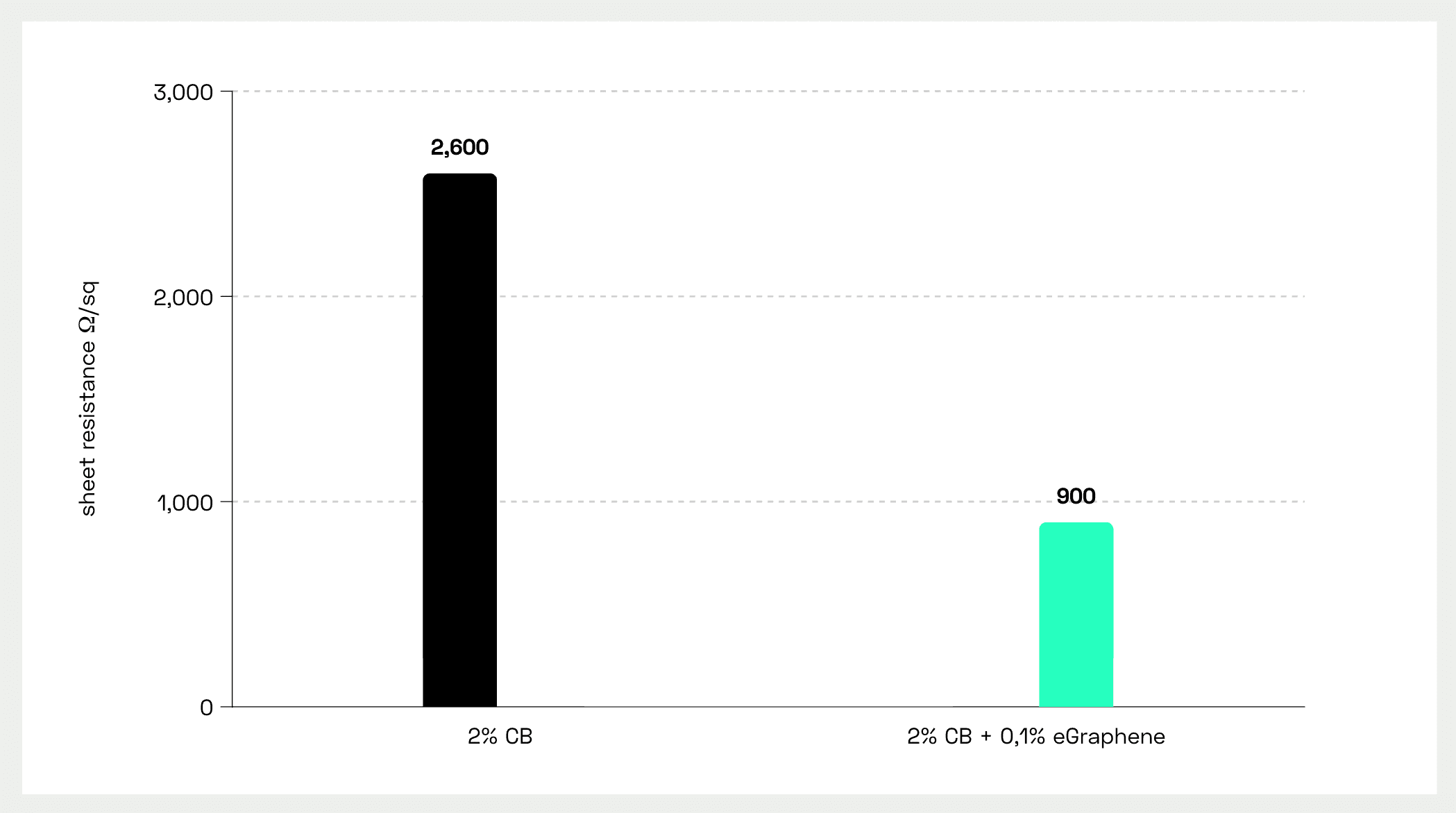

LFP cathodes vs. Carbon Black

By adding only 0,1% eGraphene, you can improve electrode conductivity and, thus, potentially reduce the amount of carbon black to achieve higher active material loadings.

eGraphene impact:

3x

More conductive LFP-cathode with 0.1% eGraphene added to 2% CB (SuperC P65)

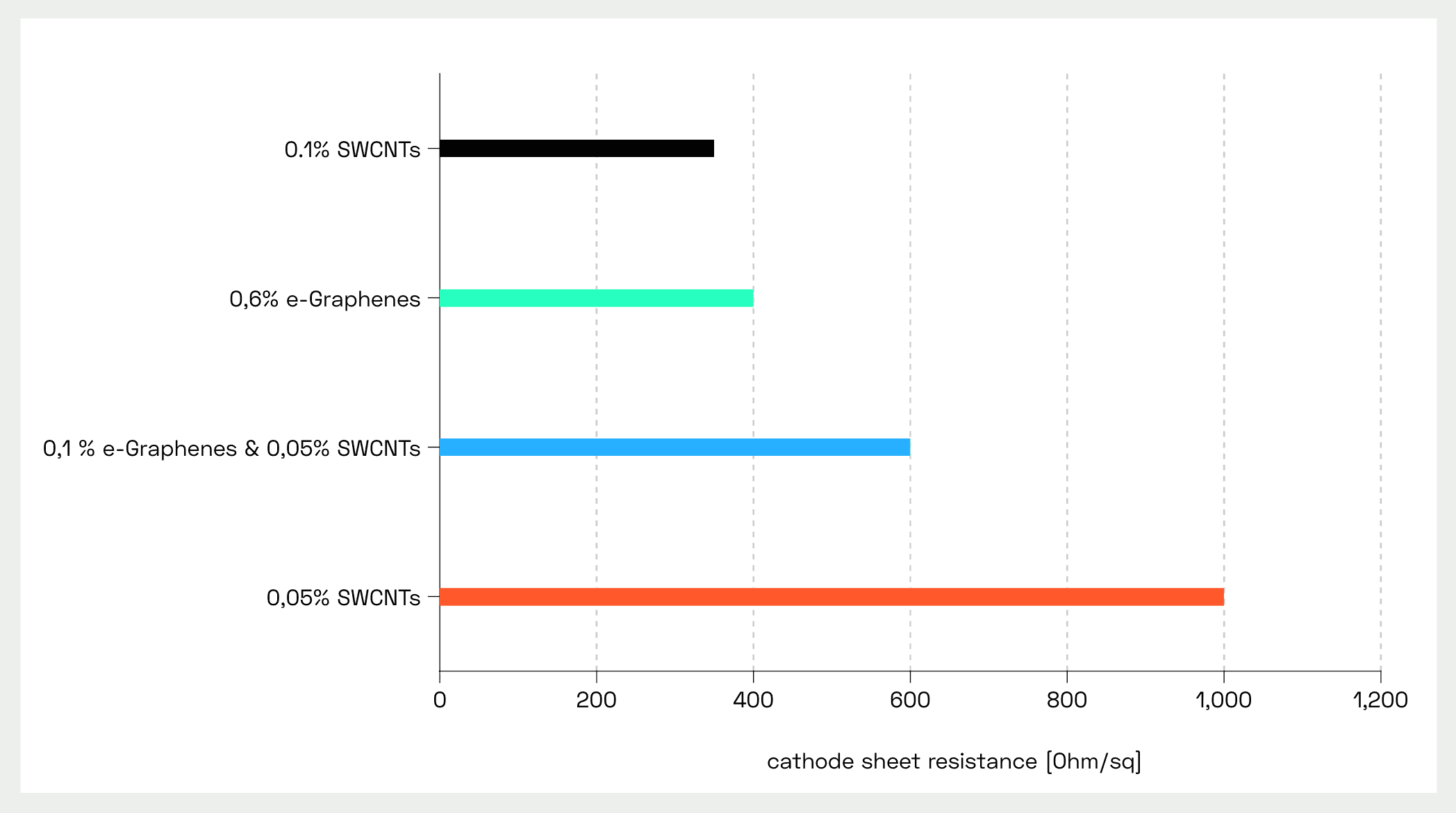

LFP cathodes compared to SWCNTs

eGraphene delivers SWCNT-performance at higher loadings but lower prices - a valid alternative for single-source supply chains.

eGraphene impact:

30x

Cheaper than SWCNTs but close to CNT performance, despite being 2D flakes

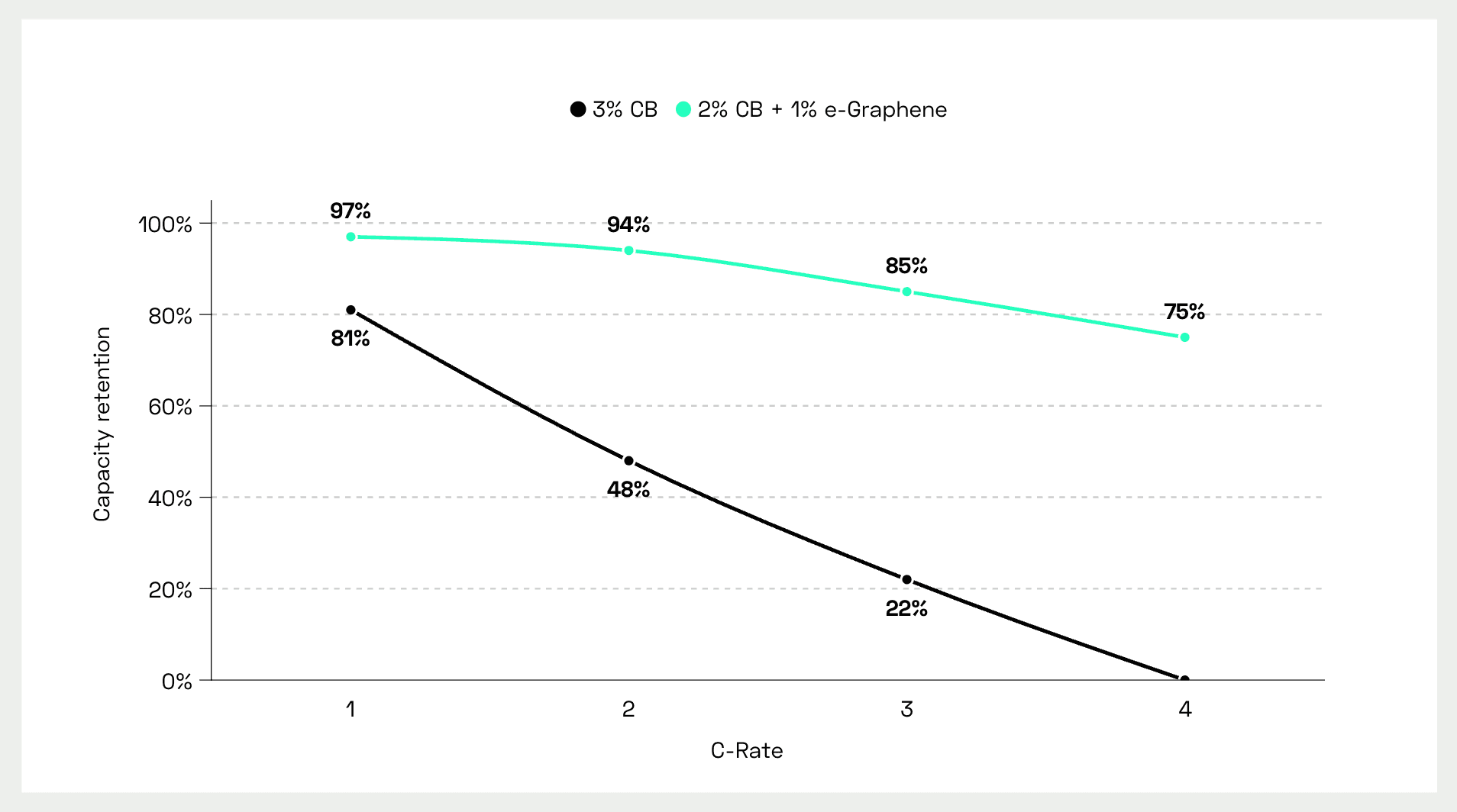

NMC cathodes vs. Carbon Black

eGraphene offers faster charging and better cycling stability at lower loadings than carbon black.

eGraphene impact:

3x

Improved charging speed by adding 1% eGraphene to 2% CB in NMC-cathodes (vs. 3% CB)

Open to a technical exchange? We’d love to dive in.

2

ANODE

PERFORMANCE

Conductivity at

Si-Anodes

eGraphene can enhance conductivity in Si-rich anodes at all states of charge when replacing graphite.

eGraphene impact:

50%

More conductive Si-rich anode with eGraphene compared to the reference with base Graphite content

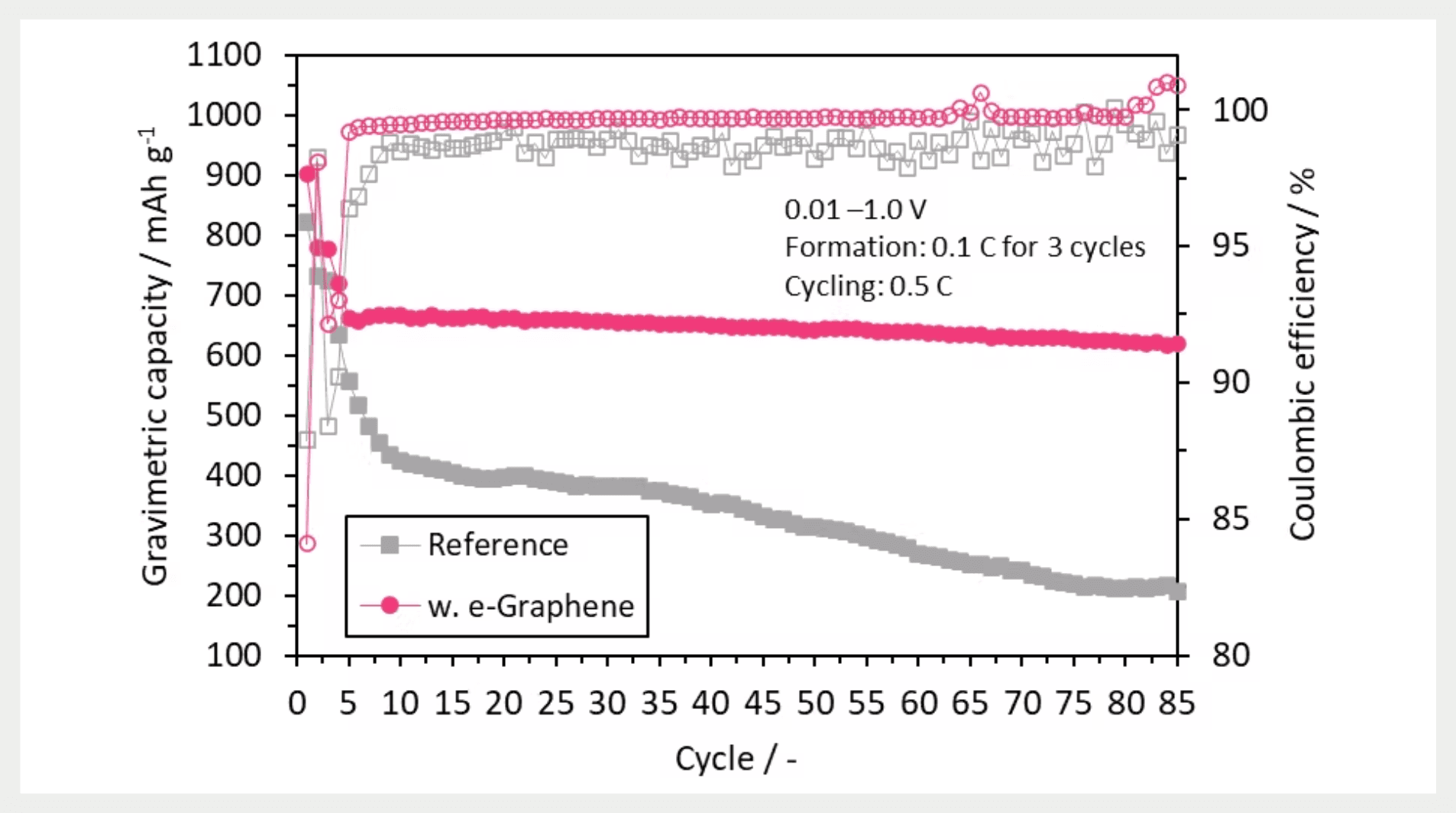

Cycling stability & FCE at Si-Anodes

eGraphene can improve cycling stability and first cycle efficiency (e.g., at Si-rich graphite anodes).

eGraphene impact:

3x

Better cycling stability and 30% better first cycle efficiency; the number of cycles required to reach >99% CE decreased from 7 to 5

Charging speeds of LTO anodes

eGraphene can enable LTO anodes with even higher cycling speeds (compared to carbon black).

eGraphene impact:

3x

Increased charging rate for LTO anode (5 min to 80% vs. 15min) combined with ~8% capacity increase

3

PROCESSING

Easy-to-use dispersions or pastes

eGraphene is available as a drop-in formulation in various solvents (NMP, water, DMF, DMSO) — completely surfactant-free thanks to in-situ functionalization. This enables stable, low-viscosity slurries without any pre- or post-processing. Unlike powders, eGraphene poses no health risks during handling or application.

SWCNTs

eGraphene

4

SUPPLY

Produced close to your factory

Our novel production approach enables local or on-site supply. Under an offtake agreement, we operate an autonomous, containerized production near or directly at your facilities.

Smoother logistics with local

or onsite supply

Save up to 90% on logistics by

avoiding dispersion shipments

Control your supply chain with

on-demand production

5

SUSTAINABILITY

We believe high-performance materials should also be sustainable. eGraphene doesn’t just improve your batteries — they improve your footprint.

Carbon Black

CNTs

eGraphene

SUMMARY

eGraphene is a true alternative to carbon black and SWCNTs, outperforming both in cost-to-performance ratio.

Carbon Black

CNTs

eGraphene

FAQ

If anything in our FAQ isn't answered, don't hesitate to contact us.

Supported by:

CONTACT

Better products start with better materials: We have 8+ years of experience applying eGraphenes to various applications and are ready to support you. Reach out to our experts.

BATTERY

USE CASES

By being 52x more conductive than carbon black and 30x cheaper than SWCNT, eGraphene is a next-gen carbon material that boosts conductivity as a conductive additive, stabilizes interfaces, and improves separator performance.

Electrode Conductive Additives

A novel conductive additive to complement or replace Carbon Black & CNTs for cathodes and anodes.

Interface & Primer Coatings

Coatings on active materials, current collectors, and other interfaces to improve cycling stability and energy density.

Separator & Membrane Coatings

Enhance or replace PFAS-based separators and membranes in redox-flow systems and fuel cells.

Don't miss a news!

Subscribe to our newsletter

CAREER

We’re scientists, engineers, and builders — working to unlock the era of 2D materials. Backed by strong funding and partners, Sixonia is scaling fast — and always open to exceptional people.