FUNCTIONAL

COATINGS

Enhance your coatings with next-generation performance — improving conductivity, strength, barrier performance, and/or thermal control through functionalized eGraphene.

10 years

R&D

10+

global patents

€ 2,6 m

total funding

50 t/a

dispersion capacity

100+

customization options

INTRODUCING

eGRAPHENE

Electrochemically-exfoliated, high-quality, processable, large-flake, few-layer graphene, based on a patented, energy-efficient, aqueous process, shipped as a dispersion, paste, or customized formulation to the customer.

Typical thickness (1-10 layers)

<3nm

Avg. flake size

~1 µm

Film conductivity up to

140.000 S/m (bulk)

Want to know more about eGraphene?

Navigate quickly to your section of interest.

BARRIER

PROPERTIES

Reduce unwanted permeation (moisture, oxygen, gases, ions) by forming a tortuous path that limits diffusion in eGraphene-enhanced coatings.

Anti-Corrosion Coatings

Challenge: Metal substrates corrode due to water or salt penetration through thin coatings.

eGraphene Impact: Creates a dense, chemically inert barrier that blocks moisture and ions, extending corrosion lifetime.

Industries / Products: Automotive, Marine, Infrastructure.

Benefit: Thinner, longer-lasting coatings; reduced blistering and underfilm corrosion.

eGraphene impact measured by customers:

7x

improved barrier performance at 0.1 wt.-%

(electrochemical impedance, DIN EN ISO 17463 / ASTM G106)

Moisture Barrier Coatings

Challenge: Polymer films (e.g., binders, packaging coatings) allow slow moisture permeation that reduces product lifetime.

eGraphene Impact: Increases diffusion path length, creating moisture-tight yet flexible coatings.

Industries / Products: Packaging films, Sensors.

Benefit: Lightweight, scalable, water-based protection with minimal additive cost.

eGraphene impact measured by customers:

3x

improved moisture barrier at 0.1 wt.-% loading.

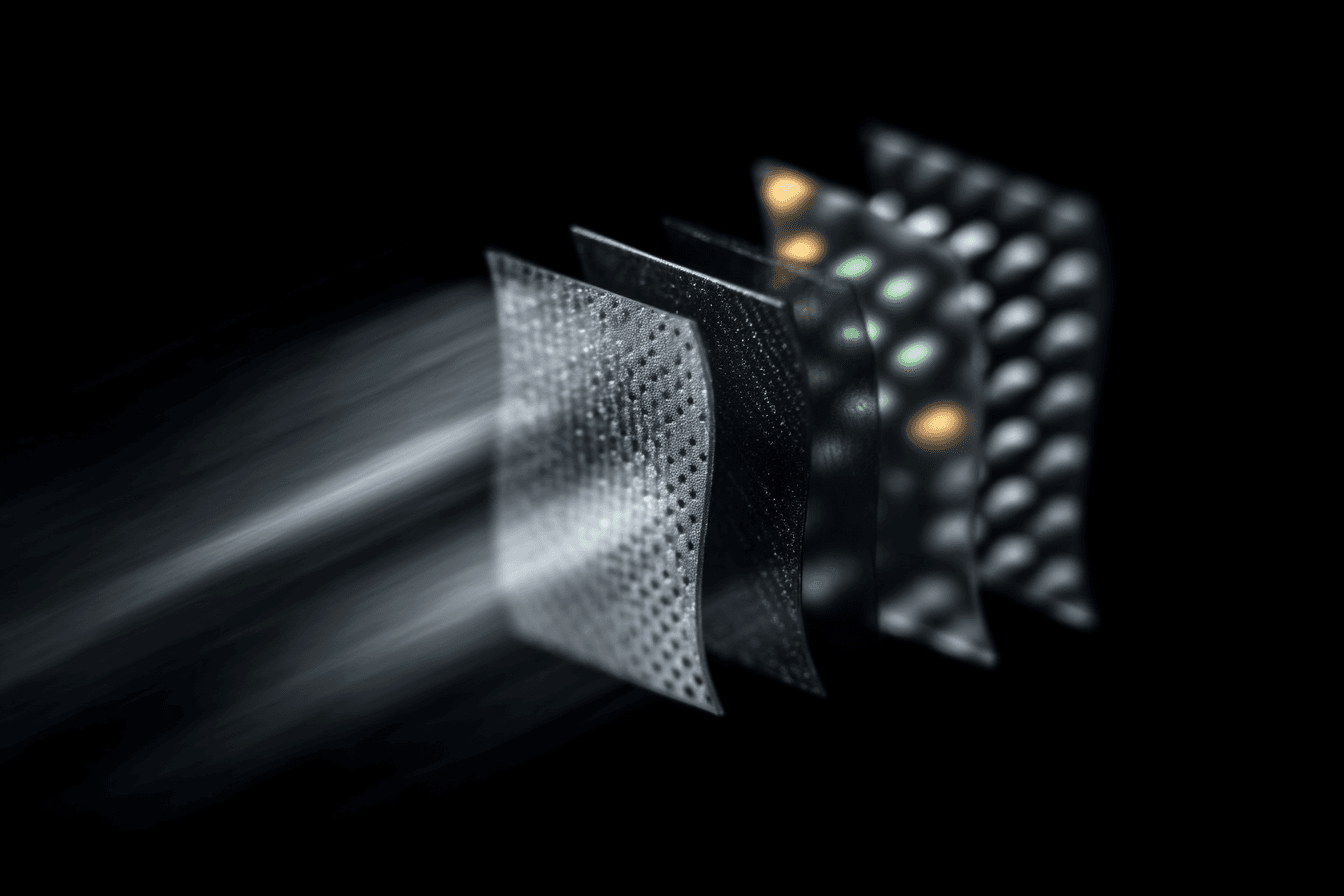

ELECTRICAL

CONDUCTIVITY

Provide electron-conducting pathways for dissipative, antistatic, EMI-shielding, or other conductive films by forming continuous, percolating networks at ultra-low loadings with eGraphene.

Radar/ EMI/ EMC Shielding

Challenge: Electromagnetic interference disrupts circuits; metal-based solutions add weight and cost.

eGraphene Impact: Creates lightweight, conductive coatings delivering strong EMI attenuation.

Industries / Products: Aerospace, Defense, Automotive, Electronics.

Benefit: 4× cheaper than silver, 8× lighter than Al foil, ideal for thin films and textiles.

eGraphene impact measured by customers:

60db

40–60 dB shielding at 12–18 GHz.

Conductive Coatings

Challenge: Printed flexible electronics require high conductivity while maintaining full design flexibility.

eGraphene Impact: Enables printable, ultra-thin conductive pathways and films for sensors, circuits, heating elements, etc.

Industries / Products: Sensors, Printed Electronics, Aerospace, Defense

Benefit: Drop-in printable inks and formulations for scalable, flexible electronics manufacturing.

eGraphene impact measured by customers:

140.000

140.000 S/m at drop casted ~34 nm eGraphene film (world record for dispersion-based graphene)

THERMAL

CONDUCTIVITY

Manage heat — either by spreading it (conduction) or by resisting it (protection) — with eGraphene, which creates an in-plane conductive network that transfers or redistributes thermal energy.

Thermal Management Coatings

Challenge: Electronic housings and composites accumulate localized heat.

eGraphene Impact: Builds continuous thermal pathways to spread heat efficiently through lightweight coatings.

Industries / Products: Electronics, Aerospace, EV battery systems.

Benefit: Rapid, even heat dissipation; prevents local overheating in thin, printable coatings.

eGraphene impact measured by customers:

50%

more thermal conductivity in a coating with <1 wt.-% eGraphene

Fire- and Heat-Protective Coatings

Challenge: Conventional coatings fail, drip, or char too quickly under flame or radiant heat.

eGraphene Impact: Forms a thermally stable barrier that delays ignition and preserves structural strength.

Industries / Products: Aerospace, Automotive, Construction, Industrial safety.

Benefit: Lightweight, flexible fire protection without halogens or ceramics.

eGraphene impact measured by customers:

20x

longer fire resistance in eGraphene-coated GF-fabric with < 1wt.-% loading

MECHANICAL

REINFORCEMENT

Strengthen resins, adhesives, and composites at ultra-low filler content by providing load transfer and crack-bridging through strong interfacial bonding with eGraphene.

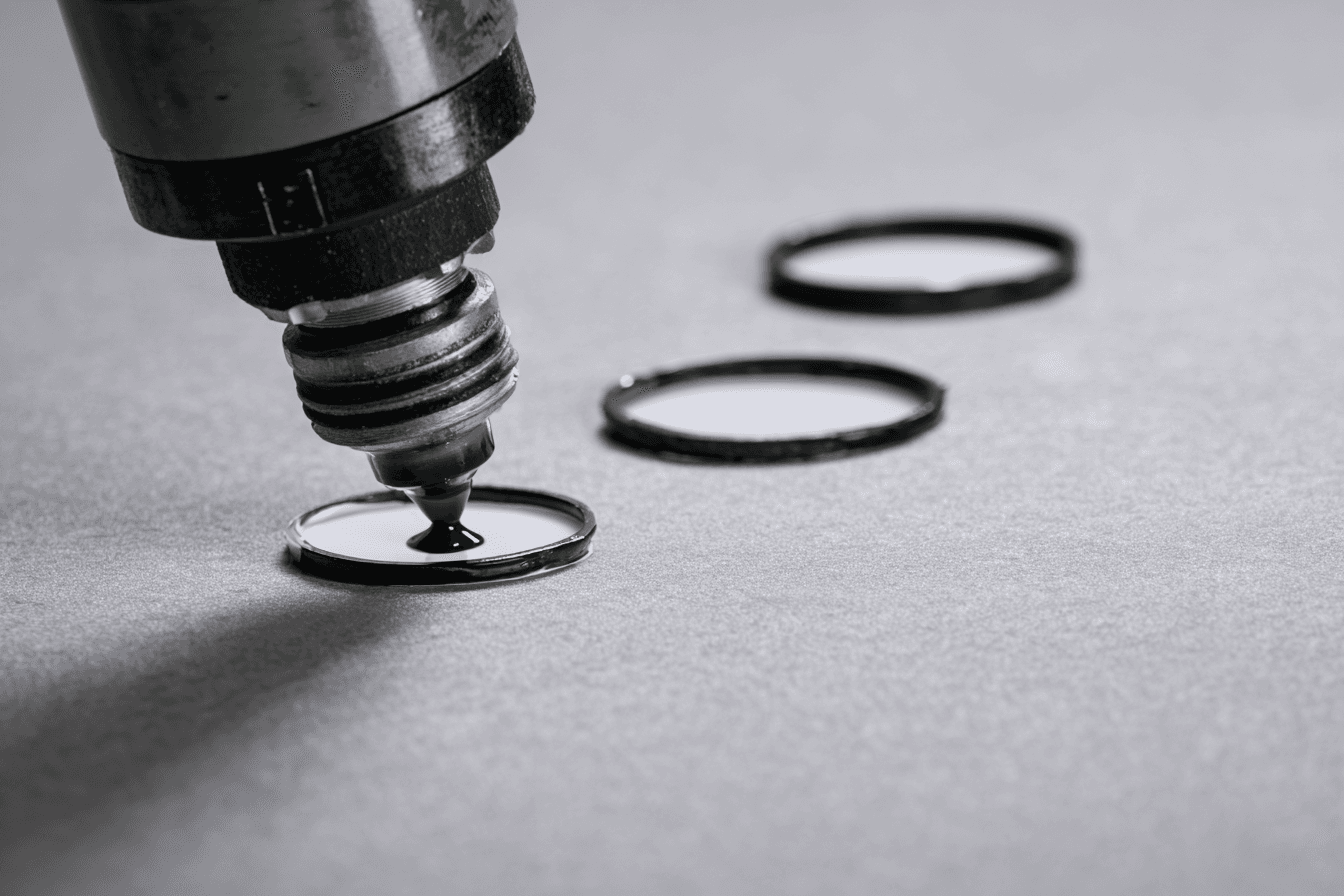

Epoxy & Adhesive Systems

Challenge: Conventional highly filled resins or adhesives crack under mechanical stress.

eGraphene Impact: Reinforces resin matrices and improves adhesion in structural applications or conductive adhesives.

Industries / Products: 2K adhesives, Conductive pastes, GFRP/CFRP laminates, Structural adhesives, Industrial composites.

Benefit: Crack-resistant, flexible bonds and laminates.

eGraphene impact measured by customers:

90%

90% - 200% improvements in fracture toughness and impact resistance at low eGraphene loadings

Anti-Erosion Coatings

Challenge: Protective coatings erode over time under abrasive conditions.

eGraphene Impact: Strengthens matrix material and helps dissipate impact forces.

Industries / Products: Aerospace, Automotive, Infrastructure.

Benefit: higher durability, low-maintenance coatings.

eGraphene impact measured by customers:

2x

higher stability in water- and sand-erosion tests at ~2 wt.-% loading

Supported by:

FAQ

If anything in our FAQ isn't answered, don't hesitate to contact us.

CONTACT

Better products start with better materials: We have 8+ years of experience applying eGraphenes to various applications and are ready to support you. Reach out to our experts.

CAREER

We’re scientists, engineers, and builders — working to unlock the era of 2D materials. Backed by strong funding and partners, Sixonia is scaling fast — and always open to exceptional people.

Don't miss a news!

Subscribe to our newsletter