eGRAPHENE

The next-generation graphene, engineered for real-world use. Functionalized, few-layered, delivered as drop-in, ready-to-use formulations.

Better products start with better materials. eGraphene delivers superior electrical, thermal, barrier, and/or mechanical properties — in a scalable, surfactant-free dispersion or paste ready for your process.

Infrastructure

Construction

Marine

Automotive

Electronics

Defense

Energy

Battery

Aerospace

Supported by:

Navigate quickly to your section of interest.

PERFORMANCE

Our patented aqueous electrochemical-exfoliation process produces large, thin, and flexible graphene flakes at low cost. eGraphene is the most conductive bulk graphene and can be customized to meet specific performance requirements.

Typical flake thickness

<3nm

No. of Layers

1-10

Film conductivity for bulk-Graphene up to

140.000 S/m

avg. lateral flake size

0.5 – 1 µm

Formulation flexibility in wt.-%

0.1 - 10%

Surfactants needed

0%

Anti-Corrosion- Coating

7x

better barrier performance

Moisture Barrier Coatings

3x

improved moisture barrier

Thermal Management

50%

more thermal conductivity

EMI/Radar Shielding

60db

shielding @ 12–18 GHz.

Epoxy & Adhesive

90%

fracture toughness

Conductive Coatings

140.000 s/m

bulk conductivity

Anti-Erosion Coatings

2x

higher stability

Fire- & Heat-Protection

20x

longer fire resistance

Open to a technical exchange? We’d love to dive in.

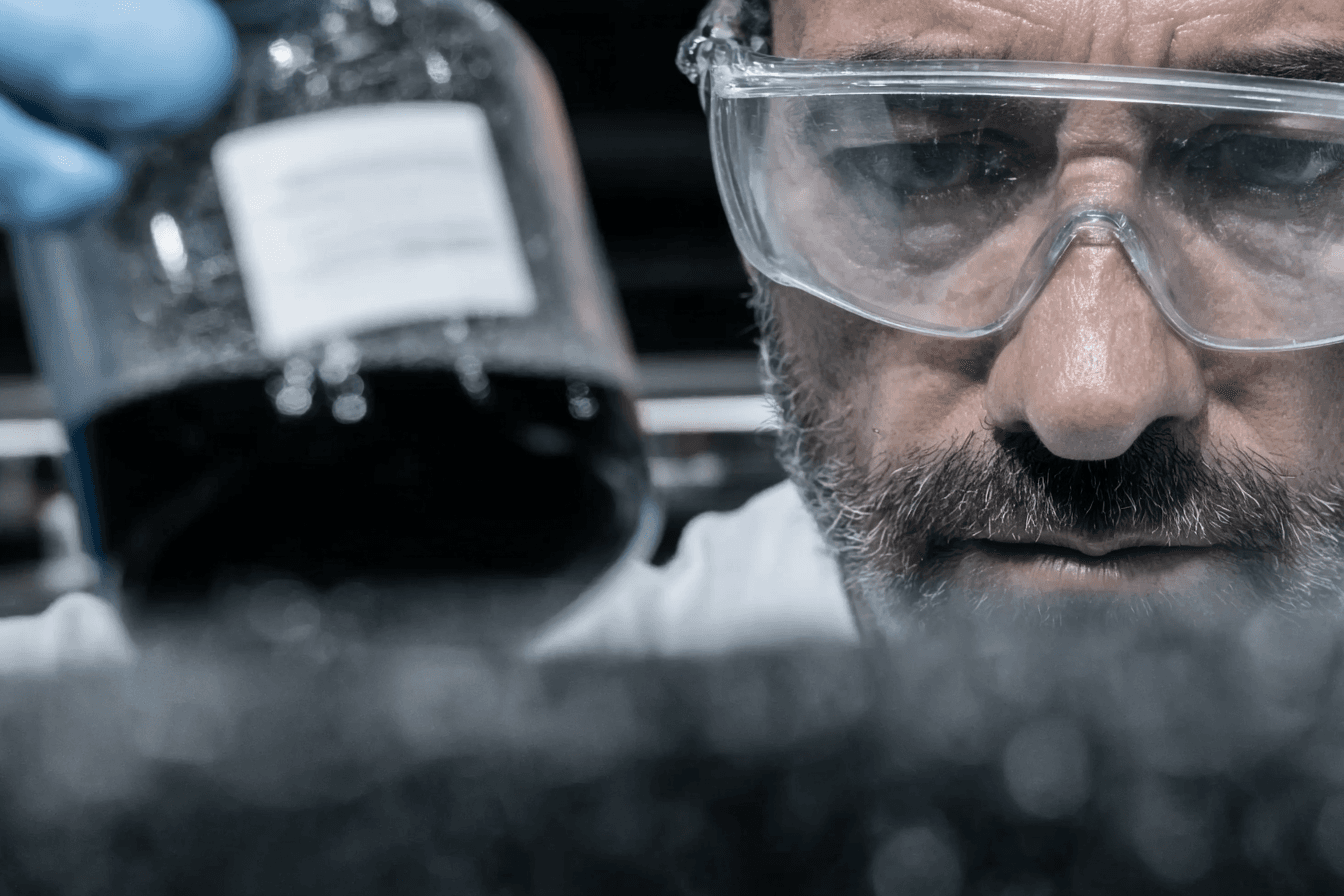

PROCESSABILITY

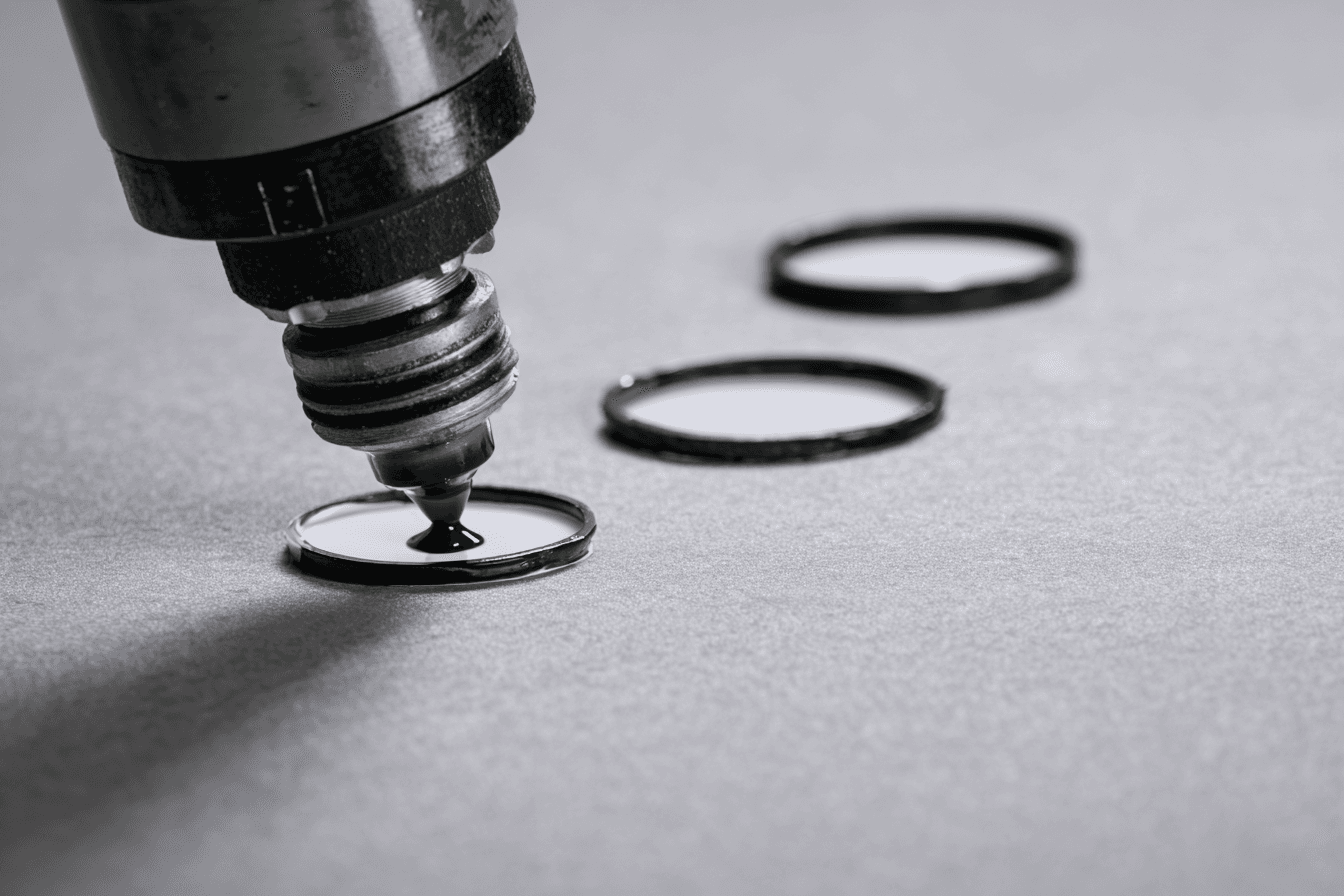

Sixonia eGraphene is functionalized to match your matrix system for true drop-in compatibility — including the world’s only stable, surfactant-free aqueous dispersion (up to 5 mg/ml).

Dispersions or Inks

Dispersions & pastes in various solvents (water, DMF, NMP, DMSO, alcohols, others) between 0,1 - 10 weight percent

Films

Free-standing or on various substrates

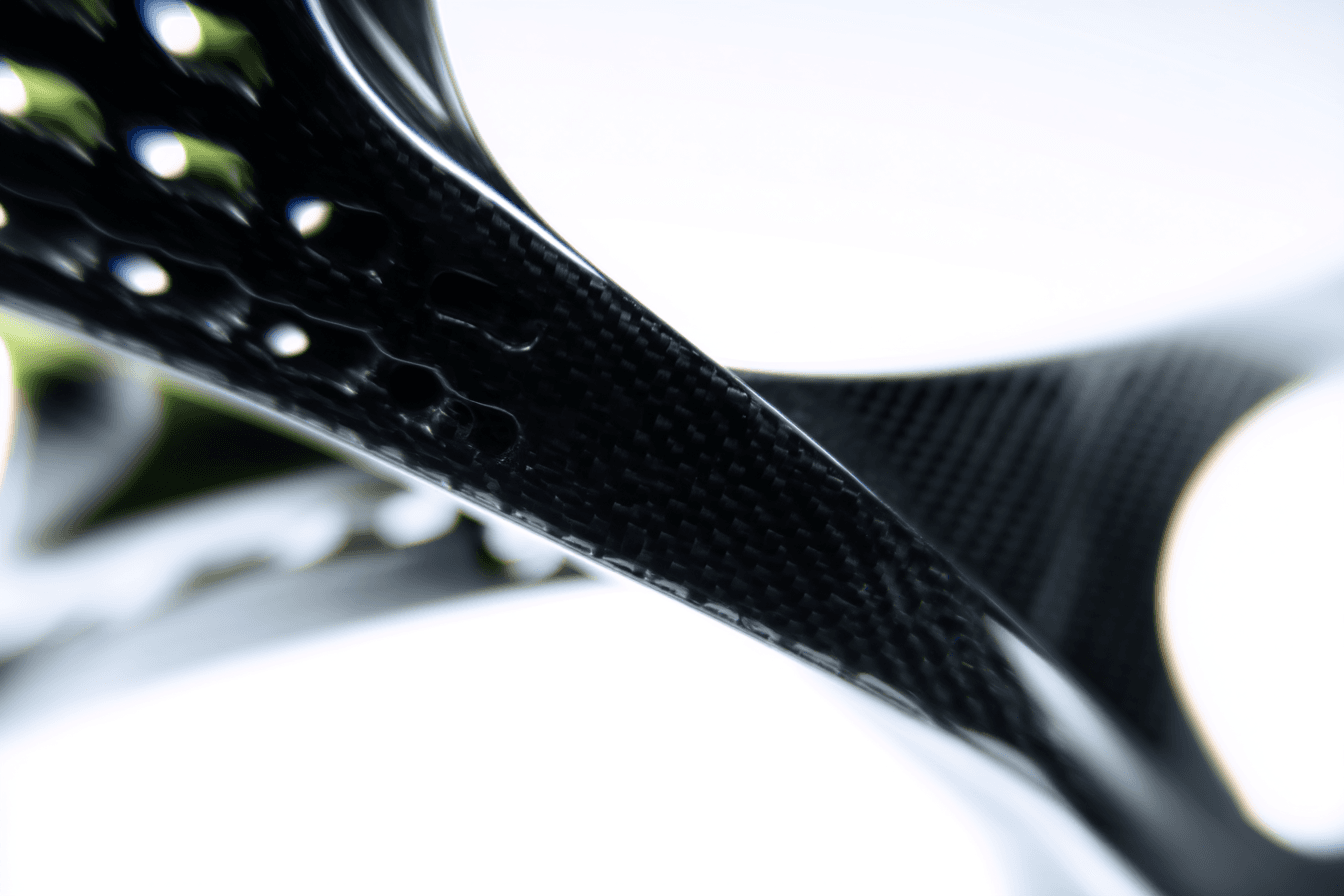

Composites

Resins & polymer composites

No surfactants or other additives

Liquid formulations without health or exposure risks typical for powders

Flexible formulations to match your matrix system and production process

Drop-in solutions that are ready to use - no pre- or post-processing needed

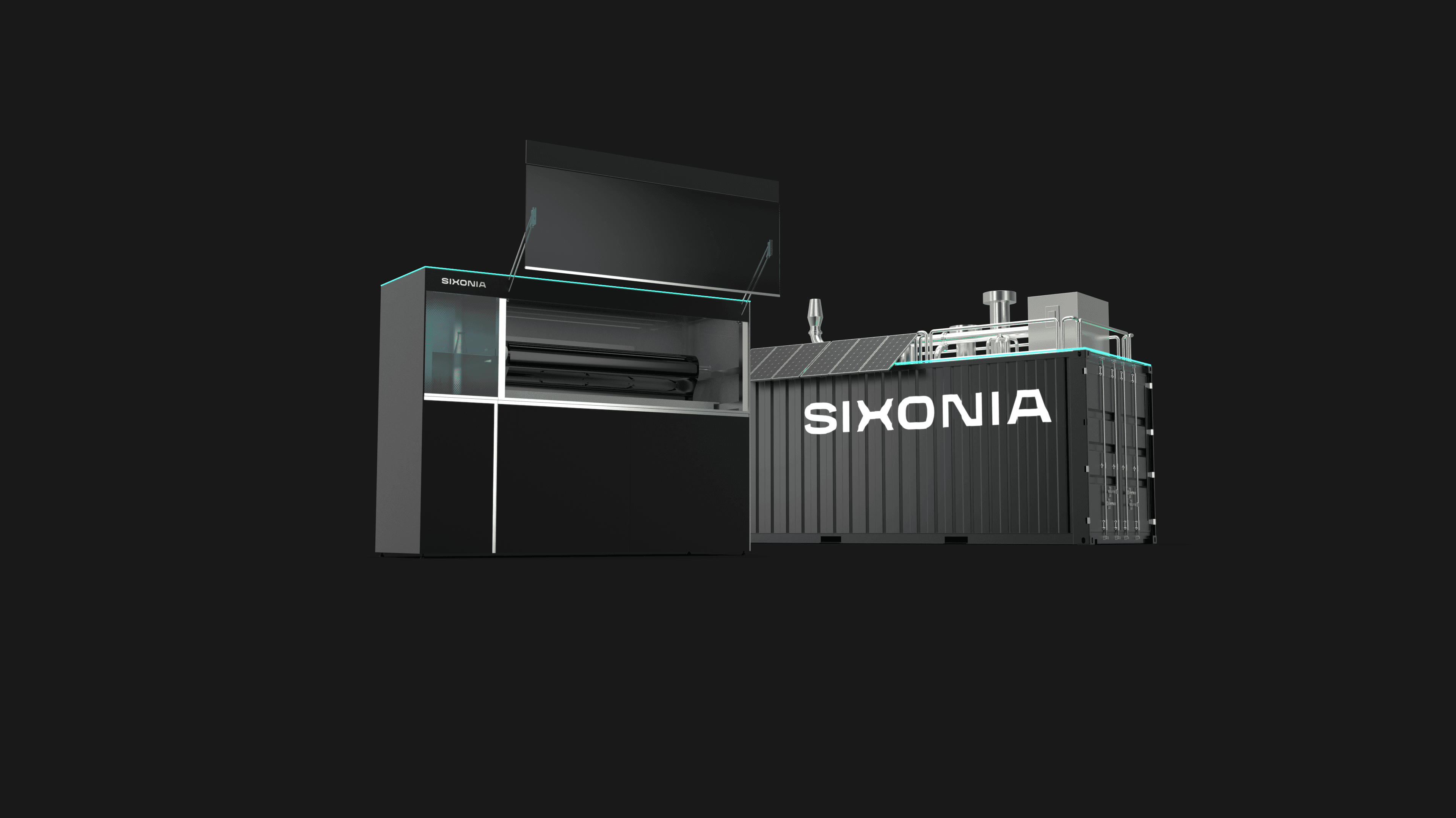

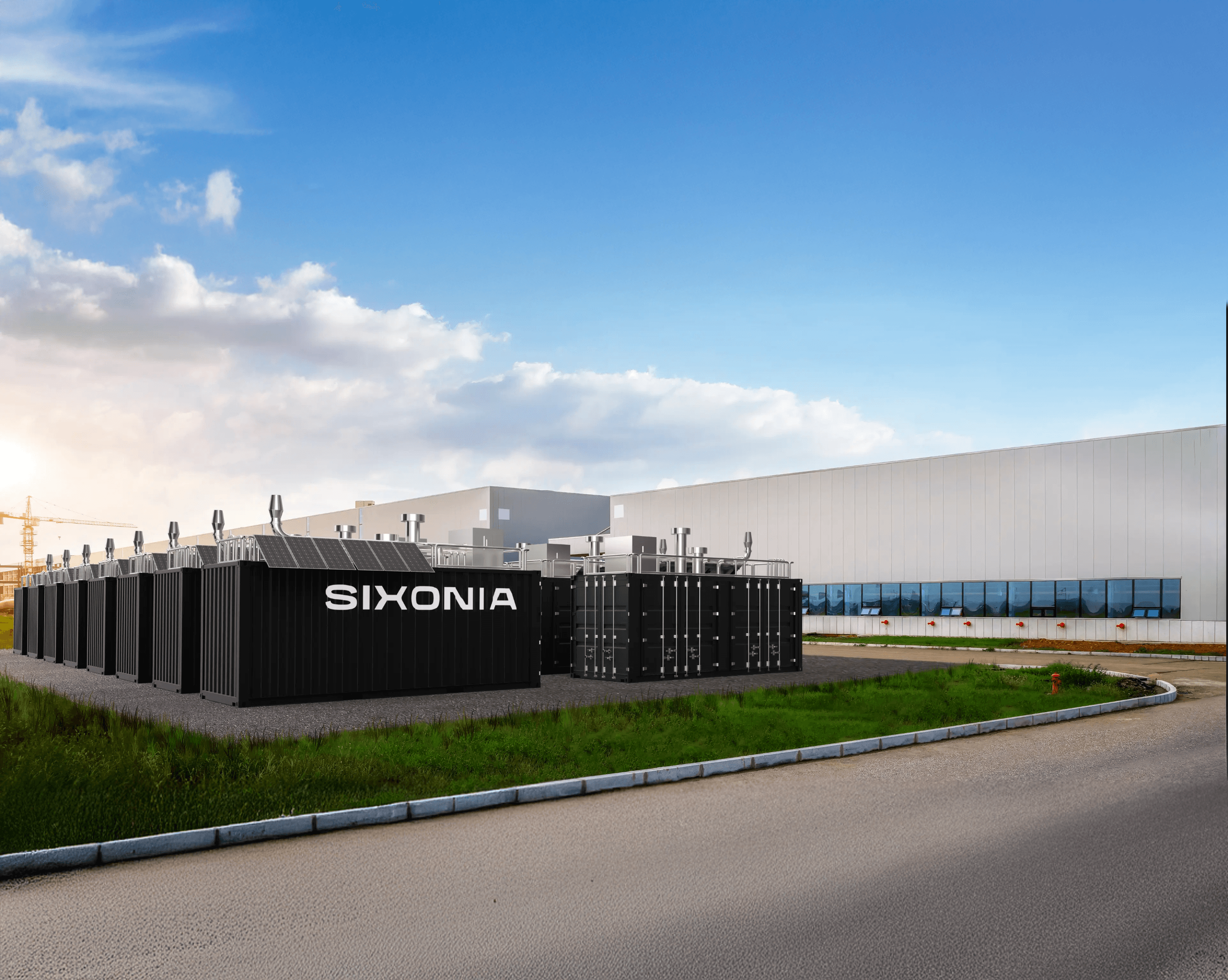

PRODUCTION

Our compact, cost-efficient process enables fully automated, modular production containers that run autonomously.

Today: 50 t/a

dispersion capacity by semi-

automated pilot production

2026+: 1.600 t/a

dispersion capacity by autonomous modular unit

Next, we plan to offer customers local or on-site production, reducing CO₂ emissions, logistics costs, and supply-chain complexity. By 2028, these containerized units will provide 10–50m t/a of eGraphene formulations.

50 t/a dispersion capacity today.

Local or onsite production possible.

Reduce logistics costs, CO₂ emissions and supply chain risks.

Comply with local regulations and avoid tariffs.

FAQ

If there is something not being answered in our FAQ, don't hesitate and contact us.

10 years

R&D

10+

global patents

€ 2,6 m

total funding

50 t/a

dispersion capacity

100+

customization options

CONTACT

Better products start with better materials: We have 8+ years of experience applying eGraphenes to various applications and are ready to support you. Reach out to our experts.

BATTERY

USE CASES

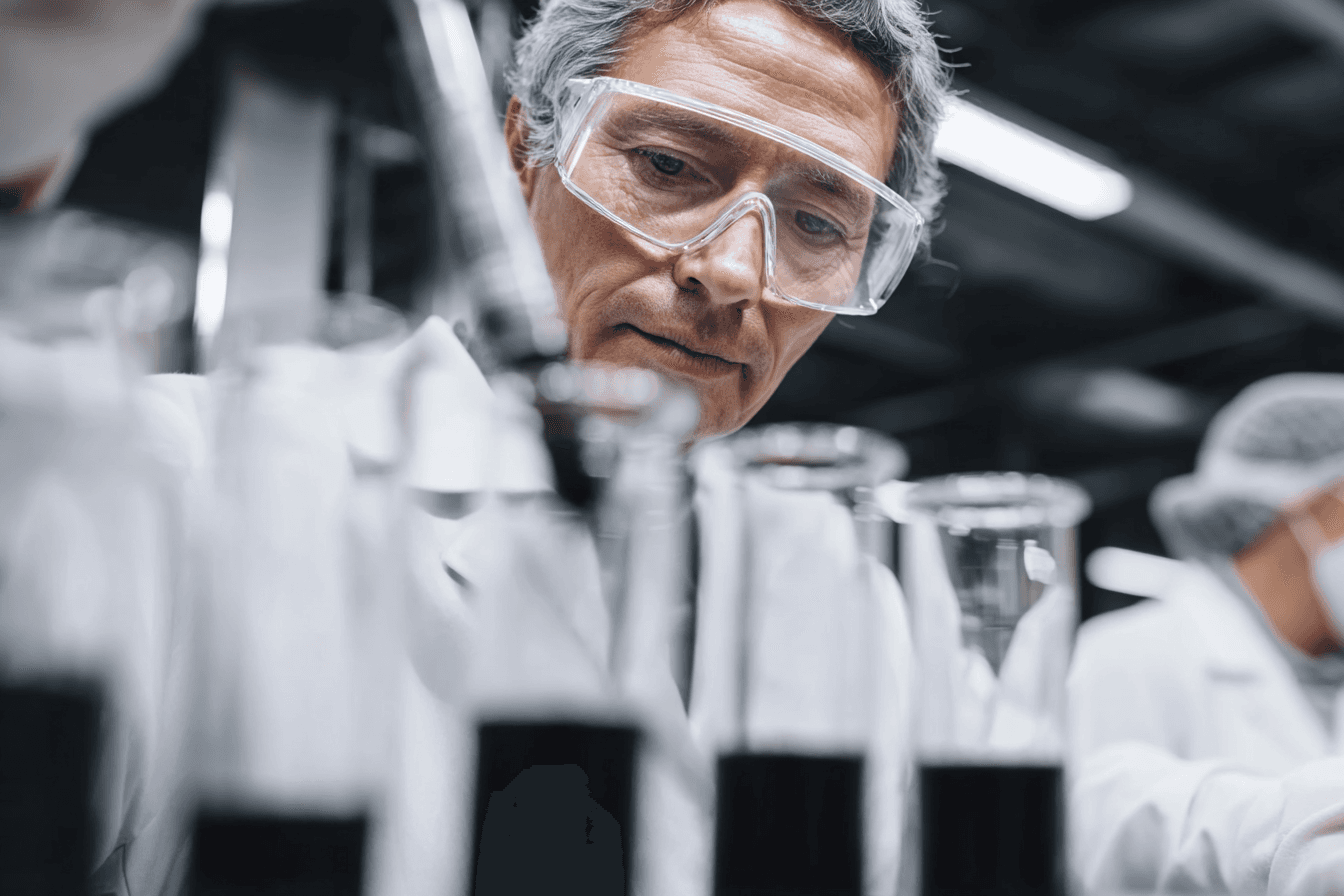

By being 52x more conductive than carbon black and 30x cheaper than SWCNT, eGraphene is a next-gen carbon material that boosts conductivity as a conductive additive, stabilizes interfaces, and improves separator performance.

Electrode Conductive Additives

A novel conductive additive to complement or replace Carbon Black & CNTs for cathodes and anodes.

Interface & Primer Coatings

Coatings on active materials, current collectors, and other interfaces to improve cycling stability and energy density.

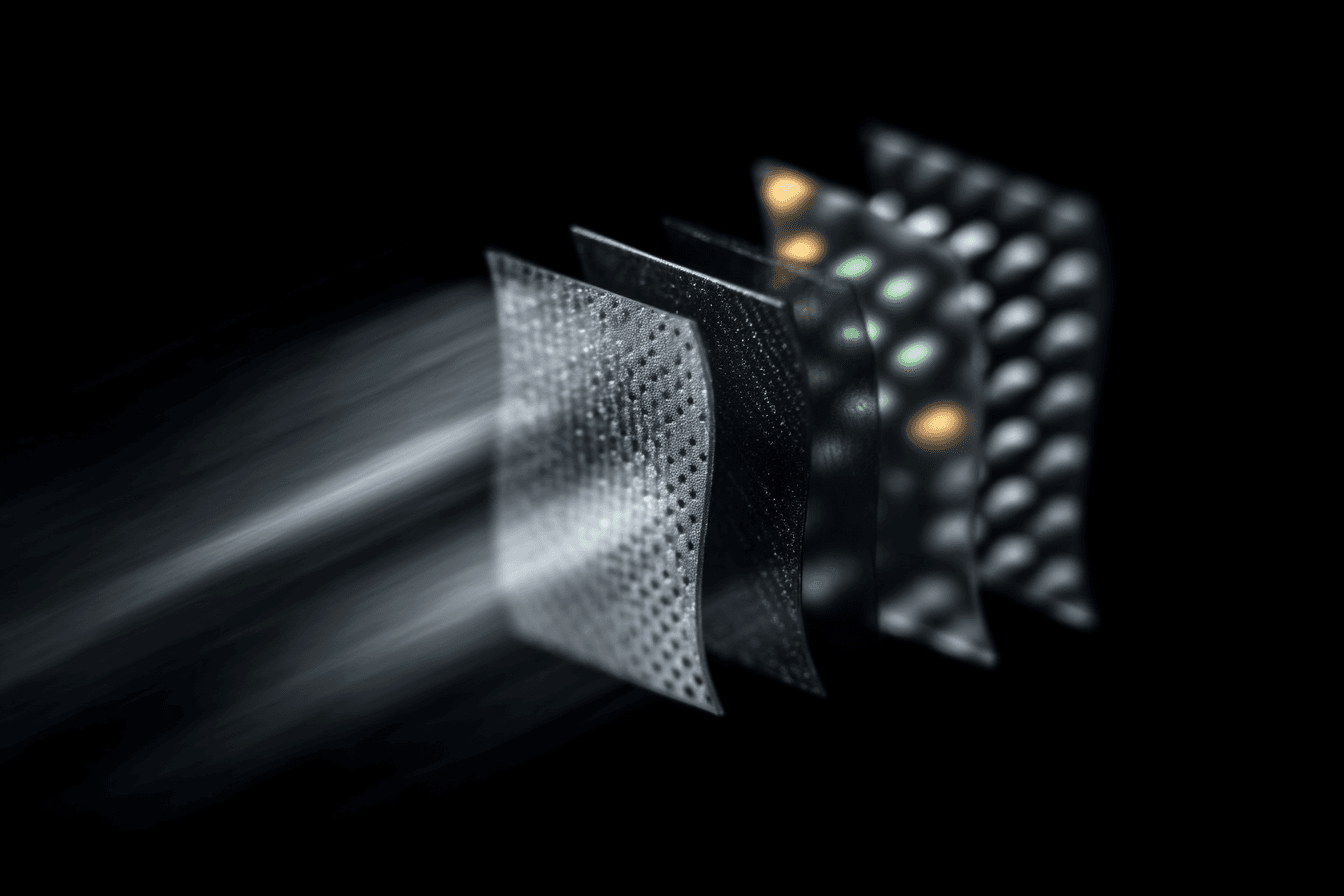

Separator & Membrane Coatings

Enhance or replace PFAS-based separators and membranes in redox-flow systems and fuel cells.

FUNCTIONAL COATINGS

eGraphene adds barrier properties, mechanical stability, electrical, and/or thermal conductivity to various coating applications.

Anti-Corrosion Coating

eGraphene forms an inert protective barrier that keeps moisture and ions away from metal surfaces— extending coating lifetime and corrosion resistance.

Fire- and Heat-Protective Coatings

eGraphene creates a thermally stable barrier that delays ignition and protects structures — without halogens or heavy ceramics.

Anti-Erosion Coatings

eGraphene strengthens the matrix material and helps dissipate impact forces, resulting in higher durability and lower maintenance coatings.

Radar/ EMI/ EMC Shielding

eGraphene enables lightweight, conductive coatings that effectively shield against electromagnetic interference — without the weight or cost of metal.

Conductive Coatings

eGraphene enables printable, ultra-thin conductive tracks and films - ideal for printed electronics, sensors, heaters, etc.

Thermal Management Coatings

eGraphene creates continuous thermal pathways in lightweight coatings — spreading heat efficiently and preventing local hotspots.

Moisture Barrier Coatings

eGraphene can increase the length of diffusion paths at miniscule loadings, enabling tighter barrier coatings without added weight.

Resin & Adhesive Systems

eGraphene reinforces resin matrices and improves adhesion in structural applications or conductive adhesives.

Want to know more about Functional Coatings?

Don't miss a news!

Subscribe to our newsletter

CAREER

We’re scientists, engineers, and builders — working to unlock the era of 2D materials. Backed by strong funding and partners, Sixonia is scaling fast — and always open to exceptional people.